Aluminium Pollution Control Systems

Aluminium Pollution Control Systems Specification

- Instruments Type

- Integrated Monitoring Instruments

- Display Type

- Digital

- Orientation

- Vertical

- Usage & Applications

- Industrial air purification, aluminium melting and casting, foundries, and metallurgical operations

- Efficiency

- Up to 99%

- Temperature

- Ambient to 60C

- Power Source

- Electric

- Automation Grade

- Semi-Automatic/Automatic

- Scrubber Type

- Wet & Dry Both Available

- Sensor Type

- Gas & Particle Sensors

- Air Flow

- Variable

- Measurement

- Air quality & particulate level

- Product Type

- Pollution Control System

- Material

- Aluminium

- Cooling System

- Water Cooled

- Noise Level

- Low

- Reactor Thickness

- 6-12 mm

- Processing Time

- Continuous

- Capacity

- 5000-50000 m3/hr

- Voltage

- 220-240 V

- Weight

- 1800-2500 kg

- Dimension (L*W*H)

- Customized

- Surface

- Anti-corrosive coated

- Fan Type

- Centrifugal/Blower

- Duct Material

- Aluminium/SS 304

- Dust Collection Efficiency

- Above 98%

- Maintenance Requirement

- Low

- Voltage Frequency

- 50/60 Hz

- Installation

- On-site by manufacturer

- Emission Level

- Meets international emission standards

- Mobility

- Stationary or Skid Mounted

- Operating Pressure

- 1000-2500 Pa

- Control Panel

- Programmable Logic Controller (PLC)

- Paint Finish

- Heat resistant epoxy paint

- Filter Stage

- Multistage (Pre-filter, HEPA, Carbon)

Aluminium Pollution Control Systems Trade Information

- Minimum Order Quantity

- 1 Unit

- FOB Port

- TKD

- Supply Ability

- 1 Unit Per Month

- Delivery Time

- 2-5 Days

- Sample Available

- Yes

- Main Export Market(s)

- Australia, North America, Eastern Europe, Western Europe, Africa, Central America, Middle East, South America, Asia

- Main Domestic Market

- All India

About Aluminium Pollution Control Systems

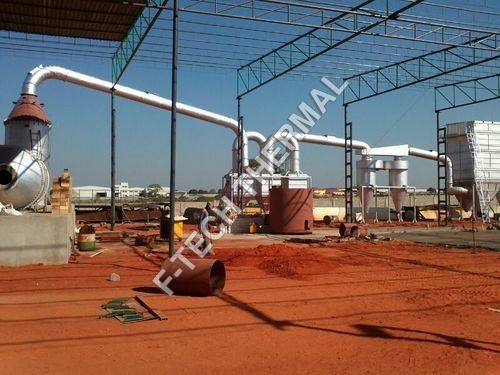

Aluminium Pollution Control Systems

Our company is providing the customers with approved and quality Aluminum Pollution Control Systems. These systems are broadly utilized for regulation and evaluation of atmospheric emissions, gases, and other pollution inducing factors. They are developed and tested under the surveillance of our controllers according to the set quality standards by using innovative technology. The provided Aluminum Pollution Control Systems are extensively appreciated because of their special features, for example, high durability, sturdiness, and reliable performance. Besides, we provide these systems in distinctive specifications at reasonable prices.

Advanced Multistage Filtration

The system uses a multi-layered approach to pollutant removal: starting with pre-filtration for larger particles, continuing with HEPA filters for fine particulates, and finally passing through activated carbon to capture gases and odours. This ensures a comprehensive purification process for industrial environments.

Sophisticated Control & Automation

Equipped with a programmable logic controller (PLC), the system offers seamless automated or semi-automatic operations. Real-time digital displays and integrated monitoring instruments allow plant operators to track air quality and particulate levels easily, streamlining compliance and performance.

Exceptional Efficiency & Compliance

Designed for demanding industrial applications, the pollution control system achieves dust collection efficiencies up to 99%. It operates at optimal air flow capacities between 500050000 m/hr, meeting international emission standards while maintaining low noise and minimal maintenance.

FAQs of Aluminium Pollution Control Systems:

Q: How is the Aluminium Pollution Control System installed at my site?

A: Installation is managed directly by the manufacturers team, ensuring precise on-site setup tailored to your operational requirements and the customized dimensions of your facility.Q: What type of filtration stages does the system include, and what pollutants does it remove?

A: The system features a three-stage filtration process comprising pre-filters for large dust, HEPA filters for fine particulates, and carbon filters for gaseous pollutants and odours. This arrangement effectively removes airborne contaminants common in aluminium processing industries.Q: Where can this pollution control system be utilized?

A: It is ideal for industrial air purification in aluminium melting and casting units, foundries, and metallurgical operations looking to comply with international emission standards and improve plant air quality.Q: What kind of maintenance is required for the system?

A: The system is engineered with a low maintenance requirement, supported by continuous processing and robust components. Regular inspections and timely filter replacements or cleaning are advisable to preserve efficiency.Q: How does the control panel facilitate system operation?

A: A programmable logic controller (PLC) controls key functions and offers digital monitoring of system parameters, delivering both automatic and semi-automatic operation modes for maximum flexibility and ease of use.Q: What are the benefits of using water cooling and anti-corrosive coatings in the system?

A: Water cooling helps regulate system temperatures during continuous operation, while the anti-corrosive, heat-resistant epoxy paint protects against harsh industrial environments, extending the equipments lifespan.Q: When should the pollution control system be operated for best results?

A: For optimal results, the system should be operated continuously during active aluminium processing, ensuring consistent air purification and compliance with required emission standards.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Air Pollution Control System Category

Lead Pollution Control System

Minimum Order Quantity : as per requirement Ton

Processing Time : Continuous

Product Type : Lead Pollution Control System

Instruments Type : Environmental Control Equipment

Material : MS/FRP

Lead Air Pollution Control System

Price Range 2000000.00 - 3500000.00 INR / Set

Minimum Order Quantity : 1 Set

Processing Time : Continuous

Product Type : Lead Air Pollution Control System

Instruments Type : Online Monitoring Instruments

Material : Mild Steel / Stainless Steel